Become a PowerPoint Guru by Dave Tracy

Become a PowerPoint Guru by Dave Tracy

Learn the methodologies, frameworks, and tricks used by Management Consultants to create executive presentations in the business world.

Become a PowerPoint Guru by Dave Tracy

Become a PowerPoint Guru by Dave Tracy

Improving Product Development competencies in designers and developers is a concern for senior leaders in the manufacturing sector.

Improving Product Development competencies in designers and developers is a concern for senior leaders in the manufacturing sector.

The approach most organizations take in developing Human Resources does not go beyond staffing the cream of the crop from leading global educational institutes. Talent Development to them is, typically, sending their people to attend workshops and keeping up with employee annual training hours’ goals, and that’s it. Companies usually spend more on acquiring latest manufacturing equipment or modern collaboration tools than they do to develop their greatest asset—their people.

Research on manufacturing practices unequivocally suggests that it’s primarily the inspiration to adopt a culture of Continuous Improvement in people that results in operational excellence. This Continuous Improvement Culture has more significance than implementing Lean practices across all processes.

The “Lean Product Development” concept isn’t a new notion. The practice has been around since the 1980s. An MIT study in the 1980s revealed that manufacturing practices in Japanese automakers were totally opposed to those of auto manufacturers in the rest of the world. These approaches were referred to as “Lean” practices. Research into manufacturing practices of Toyota has spread the knowledge about Lean Product Development globally.

Lean concept is strikingly opposing to the philosophy that emphasizes on delegating the responsibility of developing the designers’ / developers’ capabilities to the Human Resources Department. In order to develop and deliver superior products, Lean Product Development focuses on enabling the developers build “personal dexterity” as the key element of success. The concept necessitates technical training and collaboration between developers.

Before embarking on the Lean Product Development and Innovation journey, organizational leadership should work on finding answers to these 3 fundamental questions:

Pondering over these critical questions and answering them facilitates in creating a pool of skilled Product Designers and developers.

Let’s dive deeper into these questions.

Lean Product Development emphasizes on developing a steady stream of products at an even pace—referred to as “Takt.” iPhone 1 and iPhone 2 are examples of a steady stream of products released at regular intervals in Apple’s iPhone value stream.

Takt has evolved the way products are designed. An initial product is developed as a means to validate an idea. Products are progressed from the initial product based on stakeholders’ feedback. The purpose of a value stream of products is to improve the current product offerings, inspire the existing customers to upgrade, and tempt potential customers to try the product. In these evolving value streams, every product release serves as an opportunity to gain insights into the market.

The value enhancement through Takt has 2 broad objectives:

Lean Product Development underscores the significance of the medium through which developers should learn in order to create superior products. Developers’ capabilities in technical Problem Solving and learning what the others are doing helps enhance the quality of each new release. Development teams should have quick access to accumulating a thorough knowledge of the entire supply chain and the effect of their decisions on manufacturing. This assists in improving the efficiency of the developers.

Instead of learning and gaining knowledge through traditional ways, Lean Product Development encourages the developers to learn through Action Learning—the process where teams are continuously mentored and encouraged to learn collectively on the job, solve problems creatively, and test models to cope with real-life issues.

Interested in learning more about the key elements to consider before enabling Lean Product Development & Innovation, and the phases of the Lean process? You can download an editable PowerPoint on Lean Product Development & Innovation here on the Flevy documents marketplace.

You can download in-depth presentations on this and hundreds of similar business frameworks from the FlevyPro Library. FlevyPro is trusted and utilized by 1000s of management consultants and corporate executives. Here’s what some have to say:

“My FlevyPro subscription provides me with the most popular frameworks and decks in demand in today’s market. They not only augment my existing consulting and coaching offerings and delivery, but also keep me abreast of the latest trends, inspire new products and service offerings for my practice, and educate me in a fraction of the time and money of other solutions. I strongly recommend FlevyPro to any consultant serious about success.”

– Bill Branson, Founder at Strategic Business Architects

“As a niche strategic consulting firm, Flevy and FlevyPro frameworks and documents are an on-going reference to help us structure our findings and recommendations to our clients as well as improve their clarity, strength, and visual power. For us, it is an invaluable resource to increase our impact and value.”

– David Coloma, Consulting Area Manager at Cynertia Consulting

“FlevyPro has been a brilliant resource for me, as an independent growth consultant, to access a vast knowledge bank of presentations to support my work with clients. In terms of RoI, the value I received from the very first presentation I downloaded paid for my subscription many times over! The quality of the decks available allows me to punch way above my weight – it’s like having the resources of a Big 4 consultancy at your fingertips at a microscopic fraction of the overhead.”

– Roderick Cameron, Founding Partner at SGFE Ltd

Survival of a business in this digital age largely depends on its ability to timely embrace Digital Transformation. Digital Transformation entails using Digital Technologies to streamline business processes, culture, and customer experiences.

In order to compete today—and in future—and to enable Digital Transformation, organizations should work towards fostering a culture of continuous learning, since Digital Transformation depends on learning and innovation. The organizations that holistically embrace this culture are called “Next-Generation Learning Organizations.”

The next generation of Learning Organizations capitalize on the following key variables; Humans, Machines, Timescales, and Scope. These organizations incorporate technology in enabling dynamic learning. Creating Next-Generation Learning Organizations demands reorganizing the entire enterprise to accomplish the following key functions to win in future:

Next-Generation Learning Organizations make the best use of their time. They appreciate the objectives that can be realized in the short term and those that take long term to accomplish. Learning quickly and in the short term is what many organizations are already doing, e.g., by using Artificial Intelligence, algorithms, or dynamic pricing. Other learning variables that effect an organization gradually are also critical, e.g., changing social attitudes.

Rather than having people to design and control processes, Next-generation Learning Organizations employ intelligent machines that learn and adjust accordingly. The role of people in such organizations keeps evolving to supplement intelligent machines.

The Next-generation Learning Organizations incorporate economic activities beyond their boundaries. These organizations act like platform businesses that facilitate exchanges between consumers and producers by harnessing and creating large networks of users and resources available on demand. These ecosystems are a valuable source for enhanced learning opportunities, rapid experimentation, access to larger data pools, and a wide network of suppliers.

Next-generation Learning Organizations make learning part and parcel of every function and process in their enterprise. They adapt their vision and strategies based on the changing external environments, competition, and market; and extend learning to everything they do.

With the constantly-evolving technology landscape, organizations will require different capabilities and structures to sustain in future. A majority of the organizations today are able to operate only in steady business settings. Transforming these organizations into the Next-Generation Learning Organizations—that are able to effectively traverse the volatile economic environment, competitive landscapes, and unpredictable future—necessitates them to implement these 5 pillars of learning:

1. Digital Transformation

Traditional organizations—that are dependent on structures and human involvement in decision making—use technology to simply execute a predesigned process repeatedly or to gain incremental improvements in their existing processes. The Next-generation Learning Organizations (NLOs), in contrast, are governed by their aspiration to continuously seek knowledge by leveraging technology. NLOs implement automation and autonomous decision-making across their businesses to learn at faster timescales. They design autonomous systems by integrating multiple technologies and learning loops.

2. Human Cognition Improvement

NLOs understand AI’s edge at quickly analyzing correlations in complex data sets and are aware of the inadequacies that AI and machines have in terms of reasoning abilities. They focus on the unique strengths of human cognition and assign people roles that add value—e.g., understanding causal relationships, drawing causal inference, counterfactual thinking, and creativity. Design is the center of attention of these organizations and they utilize human imagination and creativity to generate new ideas and produce novel products.

3. Man and Machine Relationship

Next-generation Learning Organizations (NLOs) make the best use of humans and machines combined. They utilize machines to recognize patterns in complex data and deploy people to decipher causal relationships and spark innovative thinking. NLOs make humans and machines cooperate in innovative ways, and constantly revisit the deployment of resources, people, and technology on tasks based on their viability.

Interested in learning more about the other pillars of Learning? You can download an editable PowerPoint on Digital Transformation: Next-generation Learning Organization here on the Flevy documents marketplace.

You can download this and hundreds of other consulting frameworks and consulting training guides from the FlevyPro library.

A commonly quoted statistic is that 80% to 95% of the cost of a product is determined by its design and is therefore set before the item enters manufacturing. This  assumption suggests that the dominant focus of Cost Management should be during Product Development and not during Manufacturing.

assumption suggests that the dominant focus of Cost Management should be during Product Development and not during Manufacturing.

However, contrary to a widely held assumption, companies can integrate a variety of Cost Management techniques not only in the design phase but throughout the product life cycle. This is to ensure that there is a substantial reduction in costs. In fact, companies achieving Operational Excellence and competing aggressively on cost might consider the adoption of some form of an Integrated Cost Management Program that spans the entire product life cycle.

An organization must have a good understanding of Integrated Cost Management and the 5 Cost Management Strategies that they can use to reduce costs but still attain the desired level of functionality and quality at the target costs.

The 5 Cost Management Strategies play a crucial role in the company’s integrated approach to Cost Management.

The 5 Cost Management Strategies can be applied throughout the product life cycle with one technique used during the product design and the rest during manufacturing.

Kaizen Costing as known as continuous improvement costing. It is a method of reducing managing costs. Kaizen Costing has a similarity with Target Costing but it also has its differences. (Note: Kaizen is the Japanese term for Continuous Improvement and often tied to the philosophy of Lean Management.)

Both Kaizen Costing and Target Costing can achieve results with lower resources. This is basically their similarity. On the other hand, the differences lie in their usage and involvement.

Target Costing is used on the design stage and requires the involvement only of designers. On the other hand, Kaizen Costing is used during the manufacturing stage and requires high involvement of employees. The general idea of Kaizen Costing is to determine target costs, design products, and process to not exceed those costs.

Interested in gaining more understanding of these Cost Management Strategies? You can learn more and download an editable PowerPoint about 5 Cost Management Strategies here on the Flevy documents marketplace.

Are you a management consultant?

You can download this and hundreds of other consulting frameworks and consulting training guides from the FlevyPro library.

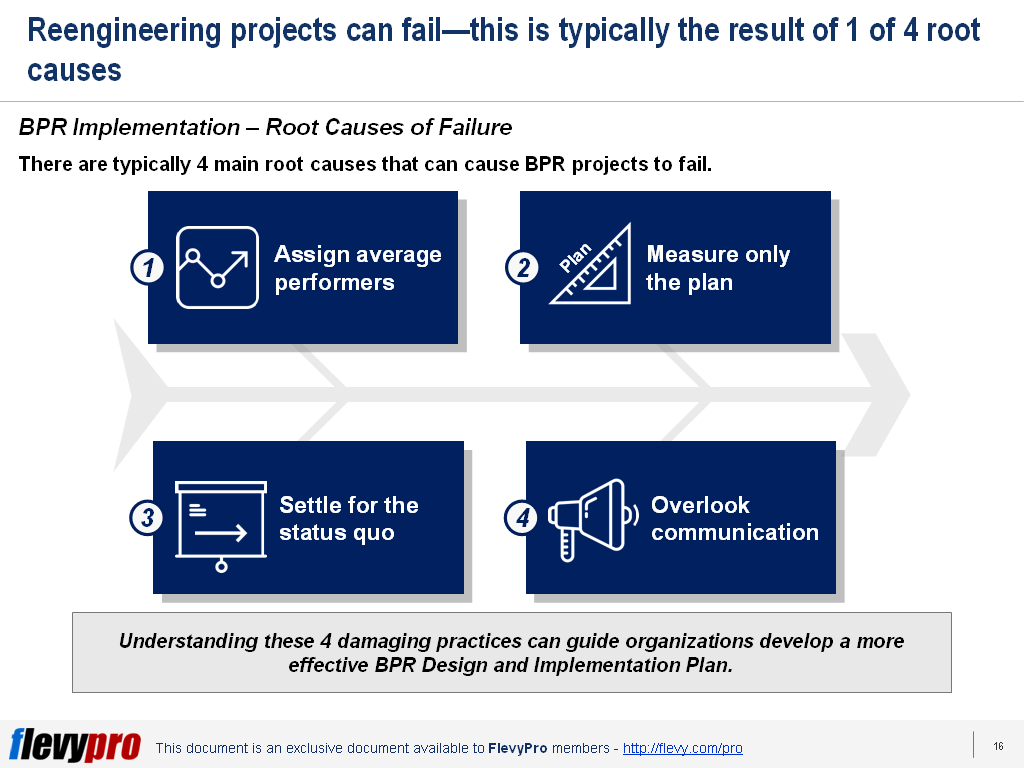

Business Process Reengineering (BPR) can be a great success but it can also be a great failure.

After months or years of careful redesign, organizations can achieve dramatic improvements in individual processes. However, a paradoxical outcome has become almost a commonplace. Organizations suddenly find themselves watching the overall results decline. Process costs were reduced by 34% yet operating income stalls. Claims process time cut by 44% yet profits drop. It seems that organizations are squandering management attention and other resources on projects that look like winners but fail to produce bottom-line results for the business unit as a whole.

Reengineering can actually deliver revolutionary process improvements and many organizations have been undertaking major reengineering effort. However, like any major change program, a reengineering project can produce lasting results only if it is designed and implemented the right way.

BPR implementation is a series of waves that can wash over the organization for years, leaving a system for continuous improvement. It must be undertaken with a clean slate approach to process design. Only then can companies avoid a classic reengineering pitfall of focusing on fixing the status quo.

Implementation of the Business Process Reengineering requires that new infrastructures are planned and built to support this Business Transformation. The full commitment of senior executives on its redesign and implementation must also be present to ensure the success of the reengineering project.

It is essential that organizations have a good understanding of the success factors, as well as root causes of failure. While reengineering projects can succeed, it can also fail. There are 4 practices that are the most damaging.

The root causes of failure remain a challenge for organizations. These are 4 causes they must watch out for to achieve a successful BPR implementation.

BPR implementation requires a small group format where employees can give feedback and air their concerns. This may be time-consuming but it is important. In fact, organizations must create a comprehensive communication program that uses a variety of methods of communication. When this is undertaken, the chances of succeeding during the BPR implementation is high.

BPR implementation is most crucial. Hence, organizations must have a keen eye, as well as strong leadership development and commitment, to pursue it despite its challenges. BPR implementation is a series of waves that can wash over the organization for years. Hence, a system of continuous improvement must be in place.

Interested in gaining more understanding of Business Process Reengineering (BPR) Implementation Guidelines? You can learn more and download an editable PowerPoint about Business Process Reengineering (BPR) Implementation Guidelines here on the Flevy documents marketplace.

Are you a management consultant?

You can download this and hundreds of other consulting frameworks and consulting training guides from the FlevyPro library.

Companies often know where they want to go when it comes to Strategy Development. Companies want to be more agile, quicker to react, and  more effective. They want to deliver great customer experience, take advantage of new technologies to cut costs, improve quality and transparency, and build value.

more effective. They want to deliver great customer experience, take advantage of new technologies to cut costs, improve quality and transparency, and build value.

Yet, while most companies are trying to get better, the results tend to fall short. One-off initiatives in separate units do not deliver big enterprise-wide impact. Improvement methods that were adopted almost invariably yield disappointing results.

Senior leaders have a crucial role to take in making things happen. Business Transformation cannot be a siloed effort. A Next-generation Operating Model is essential to break through organizational inertia and trigger step-change improvements.

Companies need to commit to a Next-gen Operating Model if they want to build value and provide compelling customer experiences at a lower cost.

The holistic Customer Journey is achieved when the 5 core capabilities are utilized.

There are 5 core capabilities essential in unlocking the most value in the shortest possible time. Two of the 5 capabilities are Digitization and Advanced Analytics.

Digitization is the process of using tools and technology to improve journeys. It has the capacity to transform customer-facing journeys by creating the potential for self-service. It has the power to reshape time-consuming transactional and manual tasks that are part of internal journeys more so when multiple systems are involved.

Another core capability worth knowing is Advanced Analytics. This is the autonomous processing of data using sophisticated tools to discover insights and make recommendations. It provides intelligence to improve decision making and enhance journeys when nonlinear thinking is required. This is very useful in claims triage, fraud management, and pricing.

There are 3 other core capabilities that are essentially important in these days of Digital Transformation. These are Intelligent Process Automation, Business Process Outsourcing, and Lean Process Design.

Intelligent Process Automation is an emerging set of new technologies that combine fundamental process redesign with process automation and machine learning. It can replace human effort in processes that involve aggregating data from multiple systems taking a piece of information from a written document and entering it as standardized data input.

Business Process Outsourcing works best for processes that are manual. It uses resources outside the main business to complete specific tasks or functions. Back-office processing of documents and correspondence is an example of BPO.

The Lean process Design is one capability that helps companies streamline processes, eliminate waste, and foster a culture of Continuous Improvement. It is considered a versatile methodology as it can be applied in multiple processes.

Organizations can use these capabilities to achieve the greatest impact. The maximum effect, however, can be achieved when specific implementation guiding principles are followed.

Interested in gaining more understanding of the Next-gen Operating Model within the context of Digital Transformation? You can learn more and download an editable PowerPoint about Digital Transformation: Next-gen Operating Model here on the Flevy documents marketplace.

Are you a management consultant?

You can download this and hundreds of other consulting frameworks and consulting training guides from the FlevyPro library.

As the last decisive step in customer service, a warehouse ensures cost effective distribution. Latest technological innovation has turned warehousing into a competitive advantage. It offers untapped potential for improvement. However, warehousing is a hugely neglected part of global supply chains. There is inconsistency in picking, packing and shipping orders, storing receipts, and managing inventory and logistics operations.

As the last decisive step in customer service, a warehouse ensures cost effective distribution. Latest technological innovation has turned warehousing into a competitive advantage. It offers untapped potential for improvement. However, warehousing is a hugely neglected part of global supply chains. There is inconsistency in picking, packing and shipping orders, storing receipts, and managing inventory and logistics operations.

These and the following roadblocks in the way of smooth warehousing operations and Lean Management exist in every traditional warehouse:

These shortcomings call for implementing Lean Warehousing methodology to unlock improvement opportunities and savings in operational, efficiency, and maintenance related costs. First initiated by Toyota, the Lean Warehousing approach has a deep emphasis on eliminating 3 basic limitations: waste, variability, and inflexibility. The Lean Warehousing methodology focuses on the following 3 improvement areas:

The Lean Warehousing methodology concentrates on increasing productivity and reducing operating costs. This is achieved by:

A Lean Warehouse seeks to take the customer quality to the next level by avoiding:

Improving service levels is at the center of a Lean Warehousing methodology, which involves:

Lean Warehousing Transformation entails streamlining operations to identify waste, know how to increase service levels, implement standardization and innovative ideas, and learn to evaluate and manage performance. Such transformation becomes a reality in an experiential learning environment and by developing organizational capabilities in 3 critical areas:

The organizational capability to configure and optimize all company physical assets and resources to create value and minimize losses. The focus areas under operating systems include eradicating variability, encouraging flexibility, and promoting end-to-end design.

The organizational capability to strengthen formal structures, processes, and systems necessary to manage the operating system to achieve business goals. The focus areas under Management Infrastructure are performance management, organizational design, capability building, and functional support process.

The organizational capability to manage the way people think, feel, and act in the workplace individually as well as collectively. The target areas to focus on here include a compelling purpose, collaborative execution, up-to-date skills, drive to improve, and committed leadership.

Lean Warehousing Transformation necessitates developing a “Model Warehouse,” which presents facilities for supply chain people to practically experience state-of-the-art warehouse operations in a modern warehouse and shop-floor environment. The Model Warehouse incorporates newest technology and systems, and offers real-life conditions for building capabilities—i.e., optimization of storage, pick and pack, and dispatch processes. Newest technologies—e.g., Smart Glasses and HoloLenses—available at the facility help improve the performance of pickers significantly and execute multi-order picking efficiently.

Such a setting allows people to observe and analyze the performance of an exemplary warehouse and implement this knowledge at their own premises. Leading organizations organize a week-long rigorous knowledge sharing workshop—in an experiential learning environment of a Model Warehouse—for their people to have a hands-on experience to learn Lean Warehousing, actual picking, packing, root cause analysis, and performance management. The participants of the Model Warehouse Knowledge Sharing Workshop are excellent candidates for “change agents” to implement Lean Transformation.

Interested in learning more about Lean Warehousing, Model Warehouse Implementation, and Lean Warehousing Transformation? You can download an editable PowerPoint on Lean Warehousing Transformation here on the Flevy documents marketplace.

You can download this and hundreds of other consulting frameworks and consulting training guides from the FlevyPro library.

Organizations need to persistently improve the way they do business to stay ahead of the curve. New ideas trigger organizational improvement and build the foundation of a Learning Organization.

Scholars have defined a Learning Organization in many different ways. Some suggest it as an organization skilled at creating, acquiring, and transferring knowledge, and at modifying its behavior to reflect new knowledge and insights. Marlene Fiol and Marjorie A. Lyles describe organizational learning as “the process of improving actions through better knowledge and understanding.” Barbara Levitt and James G. March define organizations as “Learning Organizations when they encode inferences from history into routines that guide behavior. Chris Argyris categorizes organizational learning as “a process of detecting and correcting error.” According to Peter Senge, “a Learning Organization is a group of people working together collectively to enhance their capacities to create results they care about.”

Being a Learning Organization offers several advantages. A perpetual influx of insights and new experience keeps the organization dynamic and ready for transformation; assists in better management of investments, improves efficiency; and helps in developing cost leadership and differentiation strategies. Learning Organizations tend to be more innovative by encouraging people to learn, develop, and by generating a more innovative environment. Shared learning builds the corporate image of the organization and increases the pace of change within the organization. Learning Organizations provide their people the ability to think insightfully about complex problems, take coordinated action, improve decision making, and instill a sense of community in them.

Despite efforts to improve continuously and creating new knowledge, organizations cannot simply become Learning Organizations. They employ various approaches but what they actually need is to become proficient in translating new knowledge into new ways of doing things, and actively managing the learning process so that it gets ingrained into the organizational culture.

Becoming a Learning Organization necessitates mastering 5 key activities. These 5 activities form the building blocks of a Learning Organization and should be integrated into the organizational core to transform your company into a Learning Organization.

Applying these practices to some degree or in isolated cases isn’t enough. To ensure continued success, these practices should be complemented by distinct mindsets, support systems, and processes.

Let’s now discuss the first 3 building blocks in detail.

Systematic problem solving is based on scientific methods for diagnosing problems, e.g., the Plan, Do, Check, Act (PDCA) cycle or “hypothesis-generating, hypothesis-testing.” The technique employs fact-based management, relying on concrete data instead of assumptions for making decisions and utilizes statistical tools—such as Pareto charts, histograms, correlation, and cause and effect diagrams—to consolidate data and draw conclusions.

For a real Learning Organization, people need to become more disciplined, pay more attention to detail, assess underlying causes, and analyze data before reaching decisions.

Experimentation involves systematic exploration and testing of new knowledge. Experimentation has 2 fundamental configurations; both forms transfer knowledge and yield new insights, capabilities, tools, techniques, and processes:

Ongoing programs entails a chain of small experiments aimed at yielding incremental gains in knowledge. These programs maintain a steady flow of new ideas by sending workforce on sabbaticals at different places to learn new work practices and tools from industry and academia, and applying that knowledge to their daily routines. Such programs foster risk taking and a feeling of “benefits of experimentation far outweigh the costs.”

Demonstration projects are one of a kind, large-scale initiatives that include holistic system-wide transformation targeted at a single site. These projects are executed with a goal of developing new organizational capabilities using a “clean slate” approach.

Self-managing, multi-departmental teams; high level of employee autonomy; considerable “learning by doing;” course corrections; implicit policy guidelines, precedents, and decision rules are the key characteristics of demonstration projects.

Learning Organizations gain valuable knowledge from their past experiences, by doing an exhaustive and systematic appraisal of past successes and failures. However, not too many managers pay attention to past experiences or reflect on those, eventually losing valuable insights. To inculcate a culture of learning, lessons learned should be recorded and made readily accessible to all employees.

A handful of companies have laid out processes for their managers to contemplate on their past actions and incorporate those in their learning. At the core of this approach lies the belief that distinguishes productive failure from unproductive success. Productive failure delivers knowledge and understanding whereas unproductive success goes unnoticed where nobody knows what went well and why. Learning from experience approach isn’t that expensive—case studies and project reviews can be compiled with little cost.

Interested in learning more about the building blocks of a Learning Organization? You can download an editable PowerPoint on Learning Organization: 5 Building Blocks here on the Flevy documents marketplace.

You can download this and hundreds of other consulting frameworks and consulting training guides from the FlevyPro library.

Over the last decade, companies have made greater strides in retooling their innovation  engines. Leaner and faster, products are developed from concept and delivered to customers in record time. But even a Ferrari does not know where to drive.

engines. Leaner and faster, products are developed from concept and delivered to customers in record time. But even a Ferrari does not know where to drive.

There are plenty of opportunities to enhance execution. Yet, inspiration and insights are increasingly getting to be a challenge for innovation executives. Innovation executives know that a new approach is needed. To boost performance to the next level, executives need to simultaneously loosen and tighten approaches to innovation management. We must start looking outward and opening ourselves to customers, collaborators, and our own creative side. At the same time, we need to tighten it through continuous improvement by attempting to embed an innovation culture to the organization.

Intelligent Innovation is considered a comprehensive approach that can support the next phase of Innovation Performance Improvement. The practice of Intelligent Innovation must complement the strengths of the current control regime to achieve innovative excellence.

Innovation Performance Improvement has been driven by initiatives that are highly analytical, inward-looking, and focused largely on retooling the innovation engine. There are 3 Stages of Performance Improvement. First is Management Control where innovation was treated like any other process and controlled with traditional management techniques. The second is Cost Control where innovation is redesigned to minimize cost. And the third is Profit Control where innovation was managed as projects with each project needing to be profitable in its own right.

Each successive stage built on the previous one. These stages are called “control regimes.” While these have built a critical foundation for future progress, they cannot deliver the desired results on their own.

To boost performance to the next level, Intelligent Innovation must be put in place. Intelligent Innovation completes the 4 Stages of Innovation Performance Improvement.

Intelligent Innovation cuts across 4 critical dimensions. It complements the strengths of the current control regime with excellence in 4 dimensions.

1st Dimension: Customer Insight

Customer Insight is considered the most important performance improvement level. It improves customer understanding with regards the evolving needs and critical priorities of customers. It can also increase customer participation in the innovation process.

Understanding what the customers want is important to drive ideation and execution.

According to Henry Ford, “If I’d only listened to customers, I’d have developed faster horses.”

By listening to customers, the more we learn what our customers need or want. And by knowing what our customers want, our organization will be in a better position to uncover tacit priorities that will fuel the most attractive development and innovative options.

2nd Dimension: Global Network

Global Network allows intelligent innovators to leverage dispersed knowledge across the globe. Each site or external partner is integrated into a seamlessly managed innovation network.

By having a Global Innovation Network, our organization will have the impetus to grow faster than its market.

3rd Dimension: Future Foresight

A well-tuned future trends capability can be a powerful strategic and competitive weapon in today’s global environment. It can identify tomorrow’s market opportunities and risks to drive innovation. Detailed and imaginative, this envisions the future competitive environment which better prepares our organization how to approach it.

4th Dimension: Innovation Organization

A critical element of success is the way organizations foster an innovation culture. An Innovation Organization carries within its DNA the intelligent innovation principles – senior management commitment to innovation, knowledge sharing, cross-functional teaming, freedom to pursue ideas, and innovation-friendly incentives. These are all embedded in the organization.

Intelligent innovators must work hard to unlock the innovation potential within the organization and use the tools available to direct organizations to take advantage of market opportunities. With a clear destination in mind, an innovative organization can accelerate its potential to gaining the winning edge when it comes to innovation, customer excellence, and profit.

Interested in gaining more understanding of the Dimensions of Intelligent Innovation? You can learn more and download an editable PowerPoint about Dimensions of Intelligent Innovation here on the Flevy documents marketplace.

Are you a management consultant?

You can download this and hundreds of other consulting frameworks and consulting training guides from the FlevyPro library.

Error: Twitter did not respond. Please wait a few minutes and refresh this page.