Become a PowerPoint Guru by Dave Tracy

Become a PowerPoint Guru by Dave Tracy

Learn the methodologies, frameworks, and tricks used by Management Consultants to create executive presentations in the business world.

Become a PowerPoint Guru by Dave Tracy

Become a PowerPoint Guru by Dave Tracy

Companies looking to improve efficiency and reduce costs can gain significant ground in the Supply Chain Management function by incorporating Lean Management and Six Sigma techniques.

Companies looking to improve efficiency and reduce costs can gain significant ground in the Supply Chain Management function by incorporating Lean Management and Six Sigma techniques.

Reason this area has gone under the radar is that companies do not consider Supply Chain to be their core competency.

Not only Warehousing but Transportation also has almost the same potential in terms of opportunities for Cost Reduction and Process Improvement. The approach to Transportation Costs Reduction, though, is different to that of Supply Chain Cost Reduction in Warehousing. This is in part due to the complexity in Transportation Costs, as the costs come from numerous widely distributed individual operations every year.

The approach to Supply Chain Cost Reduction in Transportation encompasses 2 phases:

Let us delve a little deeper into the 2 phases.

Improvement in Transportation operations is hindered, in most cases, by enormous variability in operations, diverse service levels being demanded by various customers, and a multitude of transport providers delivering services in a variety of ways.

Transportation Costs of between 20-30% can be saved by compiling a complete perspective of the overall Transportation operations of an organization. The evaluation will also reveal essential service categories that have a skewed effect on Cost.

Identification of the Cost Drivers is imperative for the companies to develop a systematic approach to Transportation Cost Reduction. This systematic approach involves observing 4 main levers of Cost Optimization opportunities:

The 4 levers of Cost Reductions help in countering the issues impacting Transportation Costs and enabling significant savings.

Significant Cost Reductions can be gained by identifying mutual benefits and risks for both companies and suppliers in addition to understanding customer breakpoints that enable Customer Centric Design.

Let us consider a few instances where Cost Reduction can have a quick impact.

Interested in learning more about the phases and cost drivers of Supply Chain Cost Reduction in Transportation? You can download an editable PowerPoint on Supply Chain Cost Reduction: Transportation here on the Flevy documents marketplace.

Gain the knowledge and develop the expertise to become an expert in Supply Chain Management (SCM). Our frameworks are based on the thought leadership of leading consulting firms, academics, and recognized subject matter experts. Click here for full details.

Supply Chain Management (SCM) is the design, planning, execution, control, and monitoring of Supply Chain activities. It also captures the management of the flow of goods and services.

In February of 2020, COVID-19 disrupted—and in many cases halted—global Supply Chains, revealing just how fragile they have become. By April, many countries experienced declines of over 40% in domestic and international trade.

COVID-19 has likewise changed how Supply Chain Executives approach and think about SCM. In the pre-COVID-19 era of globalization, the objective was to be Lean and Cost-effective. In the post-COVID-19 world, companies must now focus on making their Supply Chains Resilient, Agile, and Smart. Additional trends include Digitization, Sustainability, and Manufacturing Reshoring.

Learn about our Supply Chain Management (SCM) Best Practice Frameworks here.

You can download in-depth presentations on this and hundreds of similar business frameworks from the FlevyPro Library. FlevyPro is trusted and utilized by 1000s of management consultants and corporate executives. Here’s what some have to say:

“My FlevyPro subscription provides me with the most popular frameworks and decks in demand in today’s market. They not only augment my existing consulting and coaching offerings and delivery, but also keep me abreast of the latest trends, inspire new products and service offerings for my practice, and educate me in a fraction of the time and money of other solutions. I strongly recommend FlevyPro to any consultant serious about success.”

– Bill Branson, Founder at Strategic Business Architects

“As a niche strategic consulting firm, Flevy and FlevyPro frameworks and documents are an on-going reference to help us structure our findings and recommendations to our clients as well as improve their clarity, strength, and visual power. For us, it is an invaluable resource to increase our impact and value.”

– David Coloma, Consulting Area Manager at Cynertia Consulting

“FlevyPro has been a brilliant resource for me, as an independent growth consultant, to access a vast knowledge bank of presentations to support my work with clients. In terms of RoI, the value I received from the very first presentation I downloaded paid for my subscription many times over! The quality of the decks available allows me to punch way above my weight – it’s like having the resources of a Big 4 consultancy at your fingertips at a microscopic fraction of the overhead.”

– Roderick Cameron, Founding Partner at SGFE Ltd

There is a general belief among organizations that a large percentage of a product’s costs are locked in by design. It is assumed that little can be done once the  design is set. This assumption has influenced cost management programs across diverse products’ life cycles. As a result, the focus during the design phase is Cost Reduction and Cost Containment during the manufacturing phase.

design is set. This assumption has influenced cost management programs across diverse products’ life cycles. As a result, the focus during the design phase is Cost Reduction and Cost Containment during the manufacturing phase.

Yet, organizations that operated in a highly competitive market and demanded aggressive cost management showed that costs can be aggressively managed throughout the product life cycle. Various cost management strategies or techniques may be used to increase the program’s overall effectiveness. One of them is the Integrated Cost Management.

Integrated Cost Management is every organization’s prescription for lower cost and higher profits. It is the 21st business approach to achieving Cost Management efficiency.

Integration is necessary for Strategy Development as it can promote the achievement of the company’s profit objectives. In fact, there are major benefits to Integrated Cost Management. One of which is lowering of overall costs throughout the product life cycle.

Integrated Cost Management can facilitate a steady decrease in costs all the way to discontinuance. In fact, it can result in an annual cost reduction of about 17% during manufacturing, savings that exceed 30$%, and a designed-in cost of below 70%.

Achieving this requires an understanding of the Integrated Cost Management Approach.

The Integrated Cost Management Approach focuses on the integration of cost management techniques which can lead to higher levels of cost reduction and superior overall performance.

The Integrated Cost Management Approach takes into consideration 5 Cost Management Strategies.

The 5 Cost Management Strategies enable organizations to better manage costs throughout the product life cycle, with just one (1) technique taking place during the product design and the rest during manufacturing.

The application of the 5 Cost Management strategies has its key takeaways. These can be used as a guidepost in its application and a model of general concepts that organizations may consider.

One key takeaway is significant savings can still be achieved with short life cycle products and aggressive cost management focused on product design. Taking to note this key takeaway, we have to consider that as the length of the manufacturing phase of the product’s life cycle increases, the opportunity for cost reduction increases. Further, there is a need to explore the value of integrating multiple cost management during manufacturing.

Interested in gaining more understanding of Integrated Cost Management? You can learn more and download an editable PowerPoint about Integrated Cost Management here on the Flevy documents marketplace.

Are you a management consultant?

You can download this and hundreds of other consulting frameworks and consulting training guides from the FlevyPro library.

Richard Branson, British business and philanthropist once said: “One day, offices will be a thing of the past.”

While organizations still need to travel to reach their physical offices, the rapid changes in the world are requiring business

Virtual Teams work well for an organization and is effective even from a communication perspective. In fact, it is known to complement well the Lean Management approach used by organizations. Studies from previous years have shown that well-managed, widely spread, Virtual Teams have been outperforming those that share office space. In fact, it has shown that using Virtual Teams can improve employee productivity by 45%.es to form Virtual Teams. A Virtual Team refers to a group of individuals who work together from different geographic locations and rely on communication technology such as email, voice conferencing services, fax, etc.

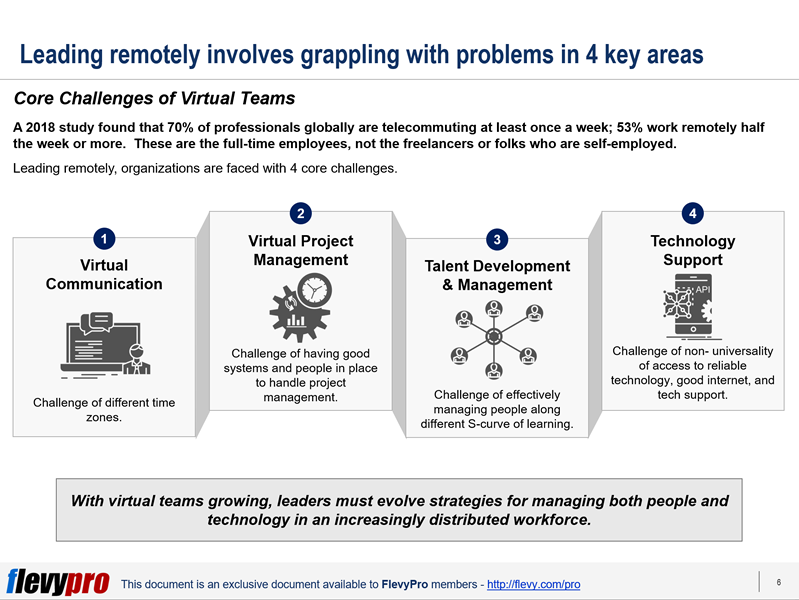

In today’s highly competitive global economy, to be able to work smarter, organizations must be able to leverage the manifold benefits of a remote workforce. Likewise, organizations must also be able to manage challenges that come with working with Virtual Teams.

More organizations are opting to work with virtual teams. Virtual teams may have their benefits but it also has its challenges. Being able to manage these challenges will enable organizations to seize the benefits of remote workers.

There are 4 core challenges that organizations face when working with Virtual Teams. Let us take a look at the 2 core challenges.

In this digital era, Virtual Teams are becoming the new face of business operation and aligning itself with Digital Transformation. This is a global reality that businesses must accept. However, working with Virtual Teams brings a lot of challenges not only in Project Management and Virtual Communication but also in Talent Development and Technology Support. Talent Development and Technology Support are two other core challenges that can make an impact on the Virtual Team. How it is managed will define the success of your Virtual Team.

In hindsight, Virtual Teams can also bring so many benefits. Hence, it is not surprising that despite the challenges, a lot of businesses still prefer to work with Virtual Teams.

One core benefit is increased access to top talent. The world has become a global market for expertise and talents. Businesses can extend their reach to other countries in their search for needed expertise. In fact, working with virtual teams will open opportunities for businesses to work with experts in various fields with various experiences. Being able to employ the best and the brightest is more than enough for businesses to continue working with Virtual Teams and conquering challenges. Businesses just need to have appropriate support programs to give Virtual Teams a home-field advantage.

Interested in gaining more understanding of the challenges & benefits of Virtual Teams? You can learn more and download an editable PowerPoint about Virtual Teams: Challenges & Benefits here on the Flevy documents marketplace.

Are you a management consultant?

You can download this and hundreds of other consulting frameworks and consulting training guides from the FlevyPro library.

Lean Management plays a significant role in putting in place processes, capabilities, and tools to improve how businesses operate. But, the  Digital Age has increased both the opportunities for businesses who know how to react and the difficulty of getting it right.

Digital Age has increased both the opportunities for businesses who know how to react and the difficulty of getting it right.

Tasks performed by humans are now more complex be it accessing information in multiple formats from multiple sources or responding to changing market and customer dynamics at an ever-increasing speed. As an increasing number of tasks become automated or taken over by cognitive-intelligence capabilities, companies need to learn from lean management. Like a sprinter who needs all her muscles to be finely tuned and working in concert to reach top speeds, fast-moving institutions must have a system to continually synchronize strategies, activities, performance, and health.

Many organizations understand the need to change how they work and have embarked on numerous initiatives, yet few have been able to get beyond isolated success cases or marginal benefits. Most companies recognize the need for a Next-gen Operating Model to drive their business forward their Digital Transformation initiatives. But, how they develop it makes a big difference.

There are 4 core pillars of a Next-gen Operating Model. Putting these in place will ensure its successful implementation.

The path to building up the Next-gen Operating Model follows well-defined approaches to guide organizations. These approaches will be every organization’s guide to operating model transformation during the first 12 months.

The 4 critical Approaches to Operating Model Transformation works well when there is a broad and top-down organizational mandate for change. Before anything else, organizations must make sure that the change mandate is in place so that the entire organization is aligned with the proposed change.

One of the 4 Critical Approaches is the Innovation Lab. The Innovation Lab is a dedicated unit set up to be entirely separate from the historical culture, decision-making bureaucracy, and technical infrastructure of the main business. It hatches new business models in an informal setting. It is best used when there is a need to move very quickly in response to market pressures.

Mastering these various approaches will enable organizations to better go through the Operating Model Transformation in the most effective way to achieve Operational Excellence.

Interested in gaining more understanding of Operating Model Transformation? You can learn more and download an editable PowerPoint about Digital Transformation: Operating Model Transformation here on the Flevy documents marketplace.

Are you a management consultant?

You can download this and hundreds of other consulting frameworks and consulting training guides from the FlevyPro library.

As the last decisive step in customer service, a warehouse ensures cost effective distribution. Latest technological innovation has turned warehousing into a competitive advantage. It offers untapped potential for improvement. However, warehousing is a hugely neglected part of global supply chains. There is inconsistency in picking, packing and shipping orders, storing receipts, and managing inventory and logistics operations.

As the last decisive step in customer service, a warehouse ensures cost effective distribution. Latest technological innovation has turned warehousing into a competitive advantage. It offers untapped potential for improvement. However, warehousing is a hugely neglected part of global supply chains. There is inconsistency in picking, packing and shipping orders, storing receipts, and managing inventory and logistics operations.

These and the following roadblocks in the way of smooth warehousing operations and Lean Management exist in every traditional warehouse:

These shortcomings call for implementing Lean Warehousing methodology to unlock improvement opportunities and savings in operational, efficiency, and maintenance related costs. First initiated by Toyota, the Lean Warehousing approach has a deep emphasis on eliminating 3 basic limitations: waste, variability, and inflexibility. The Lean Warehousing methodology focuses on the following 3 improvement areas:

The Lean Warehousing methodology concentrates on increasing productivity and reducing operating costs. This is achieved by:

A Lean Warehouse seeks to take the customer quality to the next level by avoiding:

Improving service levels is at the center of a Lean Warehousing methodology, which involves:

Lean Warehousing Transformation entails streamlining operations to identify waste, know how to increase service levels, implement standardization and innovative ideas, and learn to evaluate and manage performance. Such transformation becomes a reality in an experiential learning environment and by developing organizational capabilities in 3 critical areas:

The organizational capability to configure and optimize all company physical assets and resources to create value and minimize losses. The focus areas under operating systems include eradicating variability, encouraging flexibility, and promoting end-to-end design.

The organizational capability to strengthen formal structures, processes, and systems necessary to manage the operating system to achieve business goals. The focus areas under Management Infrastructure are performance management, organizational design, capability building, and functional support process.

The organizational capability to manage the way people think, feel, and act in the workplace individually as well as collectively. The target areas to focus on here include a compelling purpose, collaborative execution, up-to-date skills, drive to improve, and committed leadership.

Lean Warehousing Transformation necessitates developing a “Model Warehouse,” which presents facilities for supply chain people to practically experience state-of-the-art warehouse operations in a modern warehouse and shop-floor environment. The Model Warehouse incorporates newest technology and systems, and offers real-life conditions for building capabilities—i.e., optimization of storage, pick and pack, and dispatch processes. Newest technologies—e.g., Smart Glasses and HoloLenses—available at the facility help improve the performance of pickers significantly and execute multi-order picking efficiently.

Such a setting allows people to observe and analyze the performance of an exemplary warehouse and implement this knowledge at their own premises. Leading organizations organize a week-long rigorous knowledge sharing workshop—in an experiential learning environment of a Model Warehouse—for their people to have a hands-on experience to learn Lean Warehousing, actual picking, packing, root cause analysis, and performance management. The participants of the Model Warehouse Knowledge Sharing Workshop are excellent candidates for “change agents” to implement Lean Transformation.

Interested in learning more about Lean Warehousing, Model Warehouse Implementation, and Lean Warehousing Transformation? You can download an editable PowerPoint on Lean Warehousing Transformation here on the Flevy documents marketplace.

You can download this and hundreds of other consulting frameworks and consulting training guides from the FlevyPro library.

This week, LearnPPT added a new section to their site: Operational Excellence.

What exactly is Operational Excellence?

The page is currently divided into 4 main sections:

Questions, thoughts, concerns? Go to my site (learnppt.com) and shoot me an email.

For other business frameworks, visit our library of consulting-quality business frameworks and methodologies here: http://learnppt.com/powerpoint/frameworks/. These diagrams were professionally designed by management consultants. Give your presentations the look and feel of a final product made by McKinsey, BCG, Bain, Booz Allen, Deloitte, or any of the top consulting firms.

Error: Twitter did not respond. Please wait a few minutes and refresh this page.